Case

Study 3: Manitoba

Hydro Head Office, Winnipeg, MN

Type: Office

Location: , Winnipeg, Manitoba

Approximate

gross area: 64,810 m2

Number of floors above ground: 23 (including penthouse)

Year of completion: 2008

Nominator: Manitoba Hydro

Architect: Kuwabara Payne McKenna Blumberg Architects (design architects)

Smith Carter Architects & Engineers (architects of record)

Prairie Architects Inc. (advocate architects)

Energy analysis: Transolar (Energy/Climate Engineers)

for full design team click here

General

Description:

Winnipeg is the coldest city in the world with a

population over 500,000 inhabitants. It is also

the sunniest location in Canada and boasts the hottest,

most humid summers supported by the highest air

conditioner use per capita. Temperatures vary 70°C

over a year, plummeting well below -35°C in the

winter, and soaring well above 35°C in the summer.More

about climate- pdf 1.7Mb![]()

The new 64,800 m² headquarters for Manitoba Hydro is located in downtown Winnipeg. As the 4th largest electrical utility in Canada, the design of the new building had to demonstrate a commitment to energy efficiency and carbon emission reduction. A primary goal was to achieve 60% reduction below national energy standards for consumption.

The Integrated Design Process (IDP) was used to ensure the seamless fusion of the full array of goals in a holistic building solution, inclusive of design excellence, energy performance, cost effectiveness, sustainability (targetting LEED Platinum), supportive and healthy workplace, and urban revitalization

Awards:

- 2006 MIPM Architectural Review Awards - Commended for Innovation

- 2006 Canadian Architect Award of Excellence

|

The

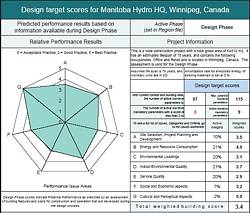

SBTool results

|

|

|

Click

to enlarge

|

|

|

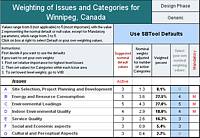

Weighting

|

Results 3.4

|

|

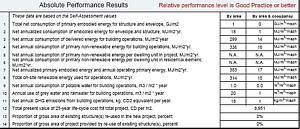

Absolute

Performance Results

|

|

MAIN SUSTAINABILITY FEATURES

- 60%

Energy Efficiency

- Project targets a 60% reduction compared to the Canadian Model National Energy Code for Buildings (MNECB). Current energy modelling suggests building will exceed a 64.5% reduction from the MNECB

- Urban Revitalization

- The design acts as a positive stimulus to downtown Winnipeg by consolidating 2000+ employees from 12 leased offices in the suburbs into one central downtown location.

- The building’s podium base is scaled to relate to the street, with a number of leasable spaces for retail and business creating an active ground plane.

- Connection to the city’s elevated path (Skywalk) system at Level 2 facilitates access for employees to downtown amenities.

- A diagonal, interior public route creates a sheltered walkway through the site, as well as a space for gatherings, special events, and exhibitions.

- At the north entrance a south and exterior ‘civic landscape’ creates an inviting and accessible public realm to reinforcing positive connections to the city. A landscaped courtyard and park facing Graham Avenue at the south entrance enhances the pedestrian environment and generates street activity.

- Supportive

Workplace

- The relocation of 2000 staff from various suburban locations into the downtown office required a cultural shift focusing on building community and promoting collaboration and teamwork. To that end the workspace strategy is based on an open concept, with an 80/20 open/private ratio of space. Open workstations are limited to 1.25m tall system partitions (a significant departure from the former 1.8m high cubicles)

- The plan creates a symbiotic relationship between the building’s respiratory system (north and south atria) and the organizing principle of vertical neighbourhoods to encourage communication, provide clear orientation, and to build community in the high rise tower. The typical net floor area of 1850m² is divided into smaller precincts organized around a series of stacked atria. The atria are connected by stairs to encourage vertical circulation and to maximize face-to-face communication and collaboration between people and departments.

- Enclosed spaces are limited to selected meeting rooms and private offices for information sensitive activities, such as accounting, legal, human resources, and executive spaces. All enclosed spaces have 2.45m demountable partitions with solid sides, glazed faces and glass transoms ensuring daylight penetration.

- User controlled automated shading and interior operable facade vents enable occupant well being.

- Radiant heating and cooling delivered to the office spaces, via the exposed overhead concrete slab, maintain consistent temperatures year round while the high thermal mass prevents apparent peak temperature loads for the occupants.

- Siting

- Building occupies a full city block, its form and massing generated primarily by solar orientation. Two towers converge at the north and splay open to the south to capture strong prevailing south winds and sunlight. North and south stacked atria fuse the masses together at each end and function as solar collectors, air exchangers, handlers and shafts. Prevailing winds that create gusting downdrafts are tamed by large canopies at the ground plane, particularly at the south grove. An interior street connects north and south entrances.

- Outdoor Terraces located on the 2nd floor of the podium are oriented to enhance daylighting into the podium office spaces.

- Passive

Building Systems

- Building form and orientation optimizes passive systems for ventilation, heating and cooling in three climatic modes: winter, summer and intermediary (shoulder) seasons.

- Maximum solar exposure and minimized north facade area take advantage of the sun’s passive warming effect on air as it moves through the south atria in the winter months and reducing thermal loss through the north side of the building

- geothermal field

- Radiant heating and cooling combined with natural ventilation (driven by stack effect at the solar chimney) minimizes the need for a typical ‘forced air’ circulation system.

- a geothermal heat pump system utilizes ground heat exchange — in winter, extracting heat from the ground to heat the building; in summer, the building is cooled, returning the heat extracted in the winter to the ground. 100% of cooling load and 50% of heating load is covered by this system.

- Indoor

Air Quality and Displacement Ventilation

- 100% fresh air year round is achieved by first drawing air into the 6-storey south atrium. There it is preconditioned by a water feature (tensioned mylar ribbons with conditioned water running down each strand to humidify ambient fresh air in winter and dehumidify in summer) before being drawn into the office’s raised access floors.

- Three and six story atria, located throughout the tower, function as solar collectors, air exchangers, air handlers, and air shafts for the building’s ventilation system. o south and north atriums act as lungs providing natural displacement ventilation via a raised floor:

- The air is supplied to the building via raised floors and is exhausted passively, via stack effect, by the solar chimney.

- High

Performance Envelope

- The exterior building envelope is a very high performing all glass unitized curtainwall assembly. The glass insulating units optimize daylight transmission (68% min) while effectively maintaining a triple glazed assembly. Overall air leakage rates are also minimized to enhance performance with target values of 0.20m³/h/m (at150Pa) of linear joint length. Mock-up testing reveal actual performance values of 0.02m³/h/m (at 150Pa), exceeding performance targets ten-fold.

- Ashlar stone assemblies on the podium, maintain the remaining facade at maximum U values of 0.227 W/m²K

- Green Roof and inverted roof assemblies further enhance the thermal performance of the building by providing maximum U values of 0.162 W/m²K.

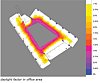

- Daylighting

and Lighting Controls

- Natural daylight is utilized throughout the building’s occupiable spaces, to enrich user comfort and reduce lighting loads.

- Automated lighting controls and dimming along with automated shading further optimize the interior environment by actively reducing Solar Heat Gain and glare.

- Ceramic frit coating on the south face of the tower lofts further passively reduces initial heat gain and glare.

- PVC free roller shade fabric with a metallised exterior face aid in the performance of the shading systems.

- Use

of Local Materials

- Products

and materials extracted and manufactured regionally

are incorporated where appropriate, and include;

- Locally quarried Tyndall stone exterior cladding.

- Concrete utilized in the foundations, structural frame, landscape and pre-cast elements consists primarily of locally sourced aggregates and sand.

- Concrete masonry units.

- Glass for the unitised curtainwall was sourced locally and prefabrication of panels was done at a dedicated local facility by the manufacturer.

- Products

and materials extracted and manufactured regionally

are incorporated where appropriate, and include;

- Resource

Reuse:

- Products and materials resource from deconstruction and demolition of existing structures, and not designated for reuse in the new building, were sold on site to the public, reused in original condition at other projects offsite, or processed for recycling.

- Old growth Douglas Fir lumber, salvaged from deconstructed site buildings, was milled and reused as soffit cladding at feature elements of the building.

- Recycled

Content:

- The primary materials of construction, for both base building and fit-up work, were specified to incorporate high-levels of recycled and / or natural materials where feasible.

- Concrete utilized in the primary structural frame and foundation caissons incorporates a minimum of 30% supplementary cementitious material (fly-ash) to reduce Portland cement quantities.

- Structural steel incorporates over 90% recycled materials.

- Reinforcing steel includes nearly 100% recycled content.

- Metal cladding includes nearly 70% recycled content.

- Composite aluminum cladding includes 40% recycled content.

- Aluminum curtainwall framing includes a minimum of 25% recycled content.

- Composite wood in millwork and partitions includes 60% recycled content.

- Acoustic panels of recycled cotton.

- Ceiling tiles include 25% recycled content.

- Demountable partition system includes 40% recycled content.

- Carpet tile containing recycled content.

- Construction

Waste management

- Existing buildings on site were deconstructed and selectively demolished in order to maximize material reuse and recycling.

- Alternative product and material reuse and recycling opportunities were researched and specified in demolition tender documents in order to ensure maximum diversion of materials from landfill.

- A formal construction waste management plan was developed and implemented during both the deconstruction / demolition and construction phases of work.

- Materials including cardboard, metals, concrete, brick, asphalt, clean dimensional wood, plastic, glass, beverage containers, and gypsum board are required to be reused or recycled.

- An exceptionally high percentage of materials, over 90% by weight, were diverted from landfills.

- Low

VOC Materials:

- Materials installed within the interior of the building contain low or no volatile organic compounds minimizing off-gassing to ensure excellent indoor air quality.

- Adhesives, sealants and sealant primers comply with VOC content limits of the State of California’s South Coast Air Quality Management District.

- Paints, coatings and primers comply with VOC content limits of Green Seal and State of California’s South Coast Air Quality Management District Standards.

- Carpet complies with VOC limits of the Carpet and Rug Institute’s Green Label Indoor Air Quality Test Program.

- Composite wood and laminate adhesive products contain no added urea-formaldehyde.

- Water Conservation

- Waterless urinals and dual flush toilets minimize water use throughout the building.

- Green Roof assemblies aid in storm water retention, reducing strain on the city infrastructure.

- In order to further reduce water consumption, a non-potable irrigation system was designed to irrigate the green roofs as well as the vegetation at street level. The water for this irrigation system is gathered from the condensate from the fan coils in the building and collected in a collection tank in the parkade. This water is then used to irrigate the landscaping.

- Occupant

Recycling & Waste Management

- Designated services are contracted by Manitoba Hydro to handle recyclable (both confidential and non-confidential documents) and waste materials in the building according to LEED Gold standards.

- Each desk, resource room, coffee bar will have designated containers for recycling; these are emptied on a per-determined schedule and delivered to recycling area managed by the service. Service will sort and remove all glass, cans, plastics, paper, and cardboard from building

- Designated Waste Management Area includes waste compactor for soiled waste.

- Hazardous materials: Materials such as batteries, spray cans etc. will be collected in designated bins and dropped off as required at the Waverly Service Centre for destruction and disposal.

- Printer Cartridges will be sent back to provider for refill.

- Transportation

- 8 prius (hybrid) vehicles for staff use

- Approximately 60 pool and fleet vehicles downtown, split between the Manitoba Hydro 360 Portage lot and a CityPlace lot (approximately 15 of the 60 will be in the lot at 360 Portage)

- staff will receive a downtown location allowance which they can put toward a 'free' bus pass if desired o free company shuttle to transport people between 360 Portage and 820 Taylor throughout the work day

- in concert with Winnipeg Transit there will be a 200 vehicle park and ride at the 820 Taylor parking lot. Winnipeg Transit will operate a direct express route from 820 Taylor to 360 Portage. Excess parking spots not utilized by Hydro staff will be sold to the public.

- Lockable storage for 100 bikes within the building’s parkade, as well bike racks at grade, encourage (with shower facilities on the second floor) healthy alternatives to motorized transit.

- Repeatability

- This project provides a viable, repeatable model for realizing a broad set of ambitions and objectives using the Integrated Design Process to achieve 60% energy efficiency, deliver a supportive workplace environment, catalyse urban revitalization, demonstrate environmental sensitivity, and balance competitive cost with design excellence within a seamless, high performance building solution. It is also an exemplar for optimizing extreme climate conditions for passive energy. Maximum flexibility in terms of floorplate, column-free spaces, raised floors and absence of ductwork will also greatly facilitate change management initiatives. Emphasis on quality of construction and enduring materials reinforces a commitment to enduring value as a form of sustainability.

- Other

information about Manitoba Hydro project:

from KPMB architects

From Google Sketchup